Contract measuring

We solve your measuring task

In our modern and climate-controlled measuring rooms, we offer first-rate options for your tactile measurement needs. Three CNC-controlled bridge-type measuring machines are ready for your measurement tasks, accommodating both touch-trigger and scanning probing systems. For non-contact optical measurements, we rely on two state-of-the-art CNC-controlled video measuring machines. This versatility allows us to cover a wide range of requirements, whether for single measurements or series measurements. Measurement sequences, especially for series measurements, can be automated on all measuring machines.

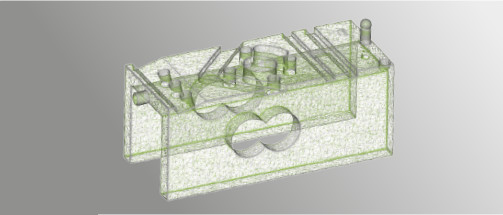

Our high-speed structured light digitizing system captures the external contours of your components at an impressive speed and precision. These captured data serve as a basis for various evaluations, such as comparison with existing CAD models, geometric dimensioning and tolerancing according to drawings, or even complex surface reconstruction within the framework of reverse engineering.

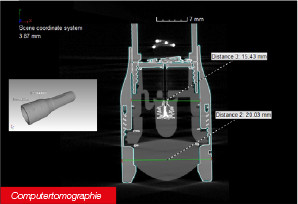

Specifically for components with complex internal contours, we rely on the capabilities of computed tomography. This enables comprehensive data acquisition and measurement of components. The generated point clouds are then used for comparisons with CAD data or serve as a basis for geometric dimensioning and tolerancing evaluations and surface reconstruction.

Our measurement processes are not only precise but also efficient. For series measurements, they can be automated and optimized to save you time and costs. We understand how crucial accurate measurements are for your production process and take pride in offering you high-quality solutions in top-notch metrology services for your needs.

Trust in our extensive experience and expertise in metrology. Contact us today to learn more about our services and solutions. We are your reliable partner for precise measurements and optimal results.

For your individual parts or small series, we supply:

- Initial sample inspection reports according to VDA

- Measuring reports for regular geometries

- Measuring reports for freeform geometries

- Analysis of geometric dimensioning and tolerancing

- Negative colour analyses against CAD data

- Measuring programmes for your use

- CAD models by surface reconstruction

Even before the production of the first part can we create complex measuring programmes offline by means of the available CAD data. This enables you to inspect your parts directly upon start of production.

Just contact us. We will find the suitable measuring technique for your parts!

Contact persons

Jürgen Brückner

Head of applications engineering

Phone: +49 (0) 23 24 / 686 4 9 17

Mail: brueckner@3d-service.com

Rainer Hielscher

Head of contract measuring

Phone: +49 (0) 23 24 / 686 4 9 17

Mail: hielscher@3d-service.com